Commitment to Progress

As an early signatory of the AIA 2030 Challenge (100% Zero-Net Energy construction by 2030) and the SE 2050 Commitment (100% Net Zero Embodied Carbon structural systems by 2050), SLAM holds a longstanding commitment to the practice of environmentally sensitive and high-performance design. SLAM embraces a culture of knowledge sharing and collaborative innovation across nine integrated offices, both in data and design methodologies.

Core Value 1:

We embrace a design culture that is data-driven to elevate, educate and strengthen our team in sustainable strategies and lessons learned.

Core Value 2:

We possess the resources to effect positive change and improve the world around us, empowering our colleagues and business partners to make sustainable choices.

Core Value 3:

Our sustainable design research initiatives must challenge our own building science achievements – strident in their innovations and collaborative by design.

AIA 2030 Commitment

Sustainability runs deep in SLAM’s culture as an integrated A/E/C practice, from project pre-planning through construction. For several decades, our leadership has encouraged cross-disciplinary teams to innovate and develop sustainable GREEN solutions with our clients and fellow design thinkers. SLAM has been reporting to the 2030 Challenge since 2010. We are collaborative… We are risk takers…We have a shared GREEN mindset. We are collaborative risk takers with a shared GREEN mindset.

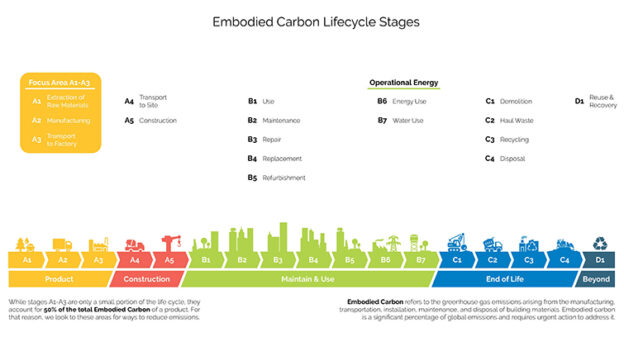

SE 2050 Commitment

SE 2050 is a commitment program established in response to growing climate concerns and solely focuses on the elimination of embodied carbon in structural building materials. The goal is to educate participating structural engineers to ultimately eliminate embodied carbon in their projects by 2050. By joining this program, SLAM is committing to a greener and more sustainable future.

Read more about SLAM’s commitment to the SE 2050 on our Design Thinkers Blog by clicking here.

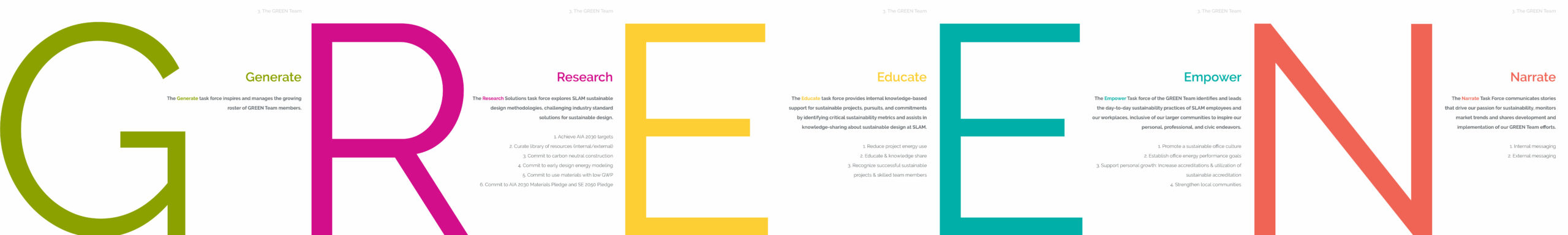

The GREEN Team is an employee-driven sustainability group supported by leadership that grew out of the firm’s dedication to the 2030 Challenge. Team members, located throughout our national practice, meet monthly and apply their interests and expertise to one or more of the five GREEN task forces: Generate, Research, Educate, Empower, and Narrate. They also serve their respective studio as peer leaders, offering sustainability oversight throughout design, construction, and occupancy of projects. The drive of the GREEN Team is to progress the culture of SLAM toward one of a “green” mindset and to celebrate sustainable design achievements of SLAM, both locally and nationally.

Members of the GREEN Team also serve as project resources to each project team. Each studio has nominated a GREEN Team member and acts as a resource for the studios. We strive to incorporate sustainability checks and balances throughout design, construction, and occupancy.

GREEN Team Spotlight: Todd Schaefer

“SLAM continues to keep pace with the “green evolution” of building materials through constant research and analysis. For example, SLAM has recently targeted foam building insulation and structural concrete due to inherently high embodied carbon, ahead of future regulations mandating their use. These sustainable materials reduce the embodied carbon footprint of our projects. Regular updates to SLAM standards (details and specifications) allows us to continually keep pace with market trends.”

Design Thinker Spotlight: Tim Applebee

“I grew up around handsaws and hammers, two-by-fours and plywood, saw dust and the fresh scent of clear pine. Thirty years later, I am an architect and design thinker at SLAM advocating for mass timber structural solutions, in part, because my grandfather was a woodworker, lumberjack, and union carpenter. He made children’s toys, built his own home, and framed out post-war skyscrapers all with wood. He taught me how to saw a straight line and how to sharpen that saw.”

Case Study: Emory University, R. Randall Rollins Building

When completed, the R. Randall Rollins Building will be one of the highest performing buildings on the campus of Emory University. The project is currently on track to achieve Gold in the LEED V4 rating system and Gold in the WELL Building rating system. It will also be the first WELL Certified building on Emory’s campus.

The project’s predicted energy use intensity (pEUI) is 44 kBTU/ft2annually, far exceeding the benchmark EUI for this type of building (100 kBTU/ft2 annually). This project makes use of chilled beams, a vegetative roof, rainwater/condensate irrigation and high performance glazing.

Case Study: Rutgers University, Richard Weeks Hall of Engineering

This new 106,000-sf, interdisciplinary facility was designed as a “living laboratory” for engineering education. The four-story facility is the flagship of both sustainability on campus and to the School of Engineering, having received LEED Gold Certification from the U.S. Green Building Council. A significant challenge to achieve, the project was earmarked as a research facility with energy challenges in the form of clean rooms (needing significant amounts of purified air), and large format classrooms with seating capacity between 30-300 students.

It displays energy performance metrics and techniques for students to view and study. It allows for demonstration opportunities for both energy research and civil engineering that can change the world. At each turn, walking through the building you are faced with design ideas improving the human experience while celebrating high-performance characteristics.

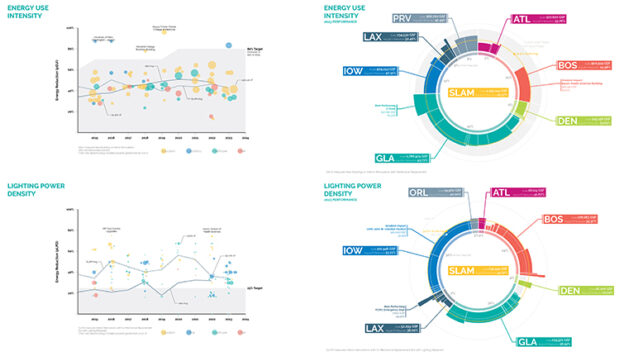

Overall Performance

– Predicted EUI improvement of 57% over baseline (105 versus 245). This includes 5,000-sf of Micro-fabrication (clean room) Lab facilities and 49,000-sf of spaces with a high (6 W/sf) Equipment Power Density allowance.

– Annual Energy operating cost savings of 29% over baseline.

– Lighting Power Density of .44 W/sf.

Energy Reduction Strategies

– Automatic lighting controls utilizing daylight and occupancy sensors.

– High performance fume hood with occupancy and sash monitors uses a fraction of the energy of standard fume hoods.

– Demand control of HVAC system by occupancy and carbon dioxide sensors.

Visit our Rutgers University portfolio page

![[DT logo]](https://slamcoll.com/wp-content/themes/sub151-SLAM/resources/images/dt-logo-dark.png) design thinkers blog

design thinkers blog